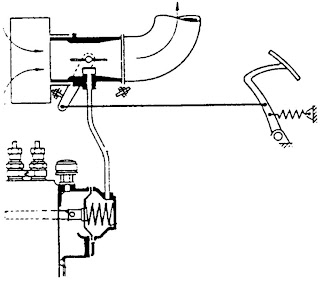

Governor pneumatic vacuum in the venturi to work depends. Vacuum has arisen to regulate engine speed = 40-80 milli bar. Pneumatic governor can regulate each round (round of idle - max rounds) and Diesel motors are used in small sizes that have a high rotation. Pneumatic governor is divided into two main parts:

a. Venturi section mounted on the engine suction channels.

b. Membrane block sections mounted on injection pump

1. The main parts

1.Air filter

2. Venturi (main and auxiliary)

3. Throtel valve

4. lever setter

5. Vacuum channel

6. Spring regulator

7. Vacuum chamber

8. Membrane

9. Atmospheric space

10. Ventilation of the atmosphere

11. Trunk control

2. How it works pneumatic governor

a. position start

Engine off, throtel fully opened, the vacuum zero. Regulator at maximum position rod.

b. idle position

Throtel on retaining the idle rotation speed big air and high vacuum regulator shaft attracted towards the stop / bit. Decrease engine speed vacuum regulator shaft pushed down towards the maximum. Rev the engine, climbed up the vacuum, and so on.

c. The position of maximum rotation and restriction

Throtel on retaining the maximum rotation, a small vacuum regulator shaft driven toward the maximum volume. The maximum rotation is reached, when the power vacuum and a spring is proportional regulator. If the engine turns up again, then the air velocity increases up = vacuum up, control rods are interested in towards the stop / bit, no reduction in the number of injections = maximum rotation in the regulation

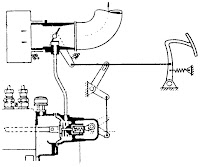

d. How to turn off the motor

1. Mechanically

Control rod is pulled toward the mechanical stop

(see picture)

2. pneumatically

With additional throtel, throtel regulatory vacuum in a very large, regulators are interested in towards the stem stop

3. additional venturi

The main functions:

• Adjust vacuum in the vacuum chamber by the injection pump airflow

• Prevent the motor turning round

How it works:

At the time of spin flipping machine, suction channel to channel exhaust. Flue gas velocity in the venturi major addition, the vacuum in the vacuum of space is also large, regulators are interested in towards the stop rod = engine died.

4. ancillary equipment

In the round of idle, less rapid cycle regulation, control rod movement from maximum to minimum is too long so the spin machine can not be stable. To prevent this additional equipment installed.

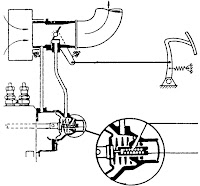

a. Additional spring round of idle with the screw setter

function:

Reduce cycle regulation that is too large so that the idle rotation can be stable Atmospheric space associated with air filters so that air flow does not affect the regulatory process.

Examples: isuzu

b. Additional spring round of idle with the switch nok

In the round of idle switch nok, an additional spring pressure so that the idle rotation cycle regulation that is too large can be minimized. Throtel When opened, the switch peak despite additional spring is not functioning anymore.

c. vibration dampers

with spuyer With rubber dampers

Function: damping vibrations in the vacuum caused by the membrane blocks the air velocity in the venturi. Spuyer Diesel motors are used in a number of cylinders 6 and 8 cylinder Gap function to avoid vibration caused by control rod lever membrane. Rubber silencer muffled thud function caused by axial movement of the lever system idle lever membrandengan

{ 3 comments... Views All / Send Comment! }

long time see you...

Look Here Best Car Service and car repaired service.

Great! thank you for sharing this useful article. We at Pneumatics Philippines can definitely use it someday.

Post a Comment